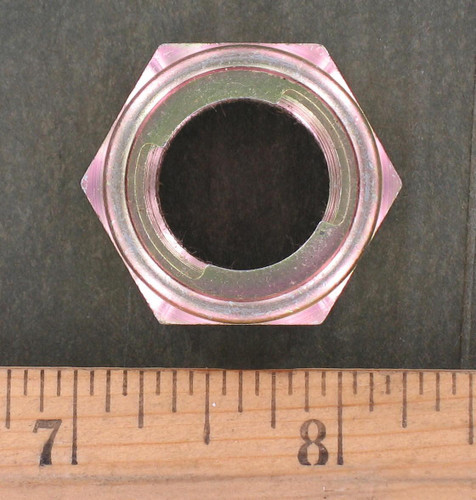

Experience superior reliability with this precision-engineered 1/4-28 Lock Nut, specifically designed for critical Aircraft Ground Support Equipment (GSE) applications. This essential hardware component ensures secure fastening across multiple GSE applications, including cargo dollies, towbars, and baggage carts, making it a versatile solution for airport ground operations.

Manufactured to meet rigorous aviation industry standards, this lock nut features a self-locking mechanism that maintains consistent torque and prevents loosening under vibration – a crucial safety feature in high-traffic airport environments. The 1/4-28 thread specification provides optimal thread engagement, while the corrosion-resistant finish extends service life and maintains structural integrity in demanding outdoor conditions.

Compatible with standard 1/4-inch bolts featuring 28 threads per inch, this lock nut seamlessly integrates with existing GSE maintenance protocols. Its unified thread design facilitates quick installation and replacement, reducing equipment downtime and maintaining operational efficiency. The precision-machined threads ensure consistent fit and reliable performance across all specified GSE applications.

Airport maintenance teams particularly value this component for its dual benefits of secure fastening and ease of maintenance. The lock nut's design allows for repeated use without compromising its self-locking properties, providing a cost-effective solution for regular maintenance cycles. Whether securing towbar components or maintaining cargo dolly assemblies, this lock nut delivers consistent performance in critical ground support operations.

Key applications include:

- Securing pivot points on cargo dollies

- Fastening towbar components

- Maintaining baggage cart structural integrity

- Critical joint assemblies in GSE equipment

This essential GSE component meets or exceeds standard aviation hardware specifications, ensuring reliability in airport ground handling operations. For optimal performance, always verify torque specifications according to your equipment's maintenance manual and replace any lock nuts showing signs of wear or damage.

| Make | Model |

|---|